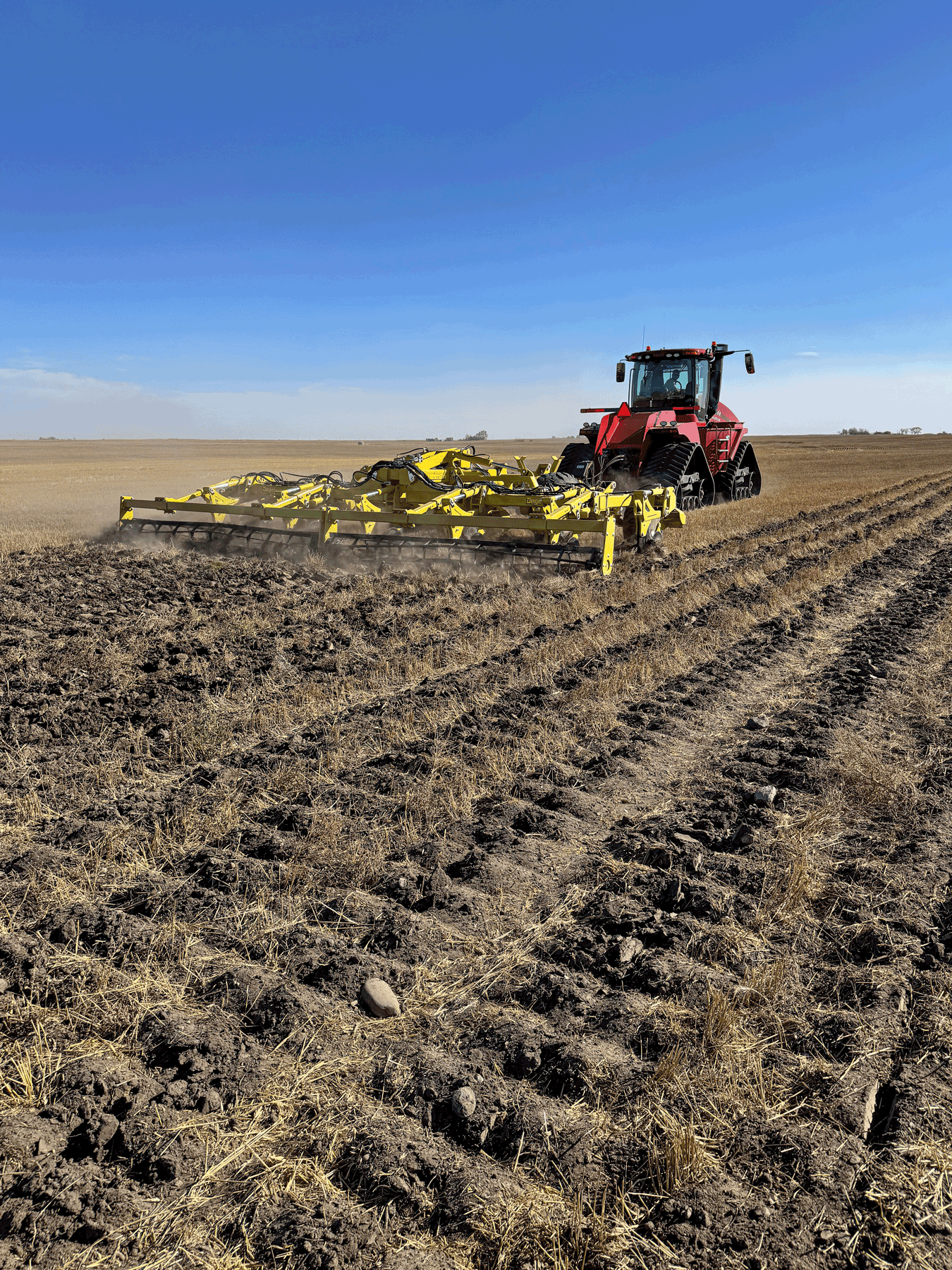

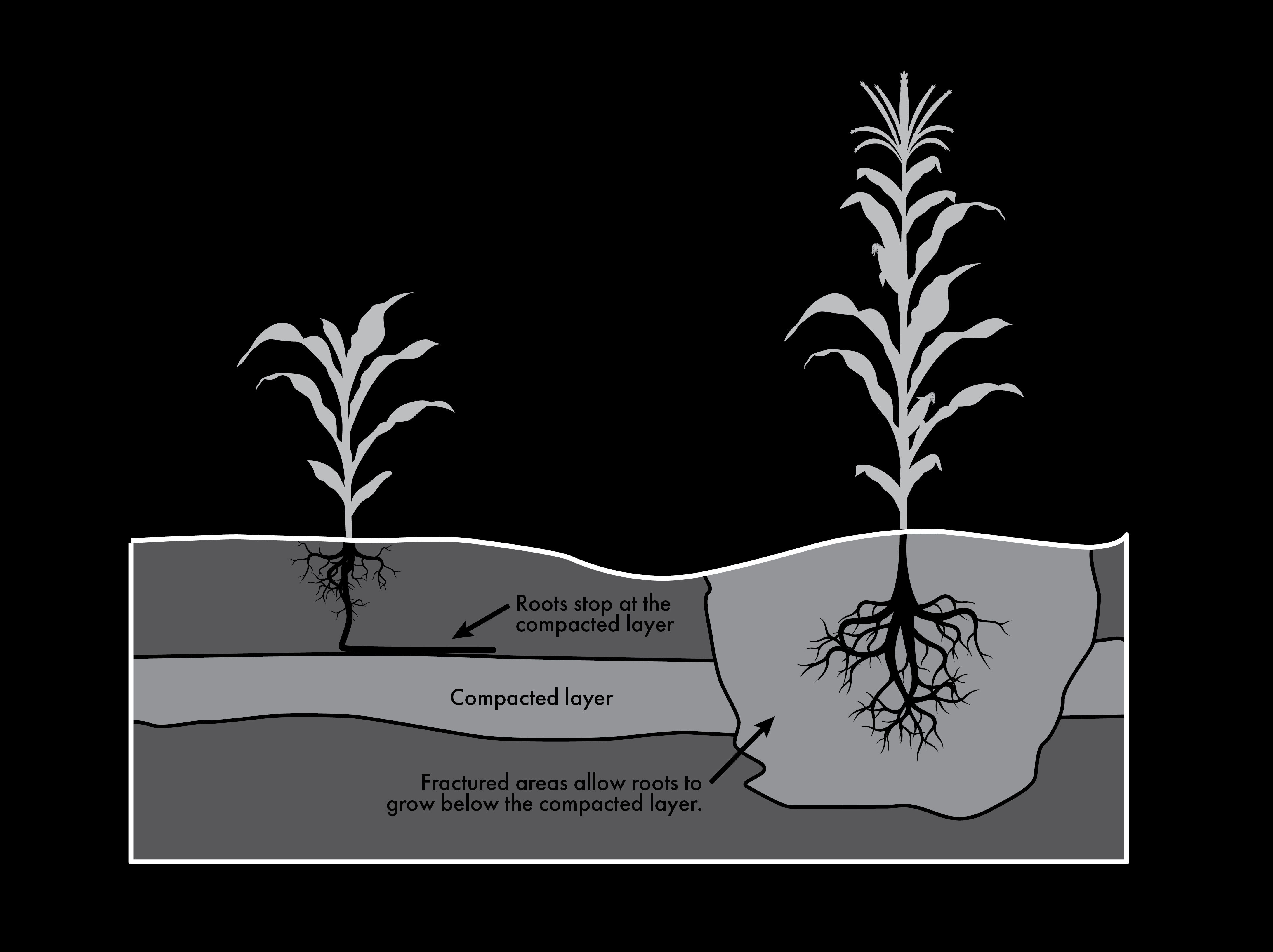

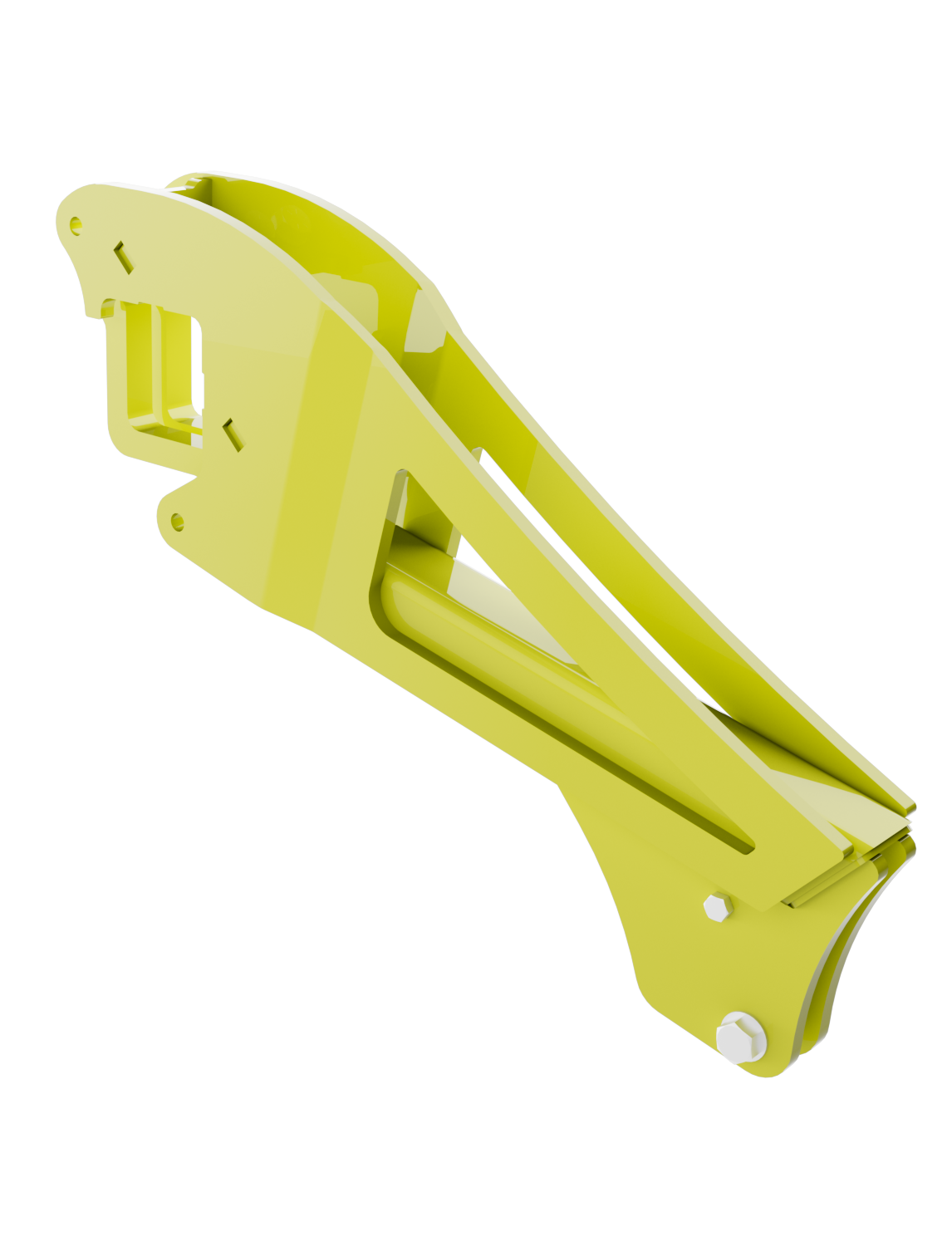

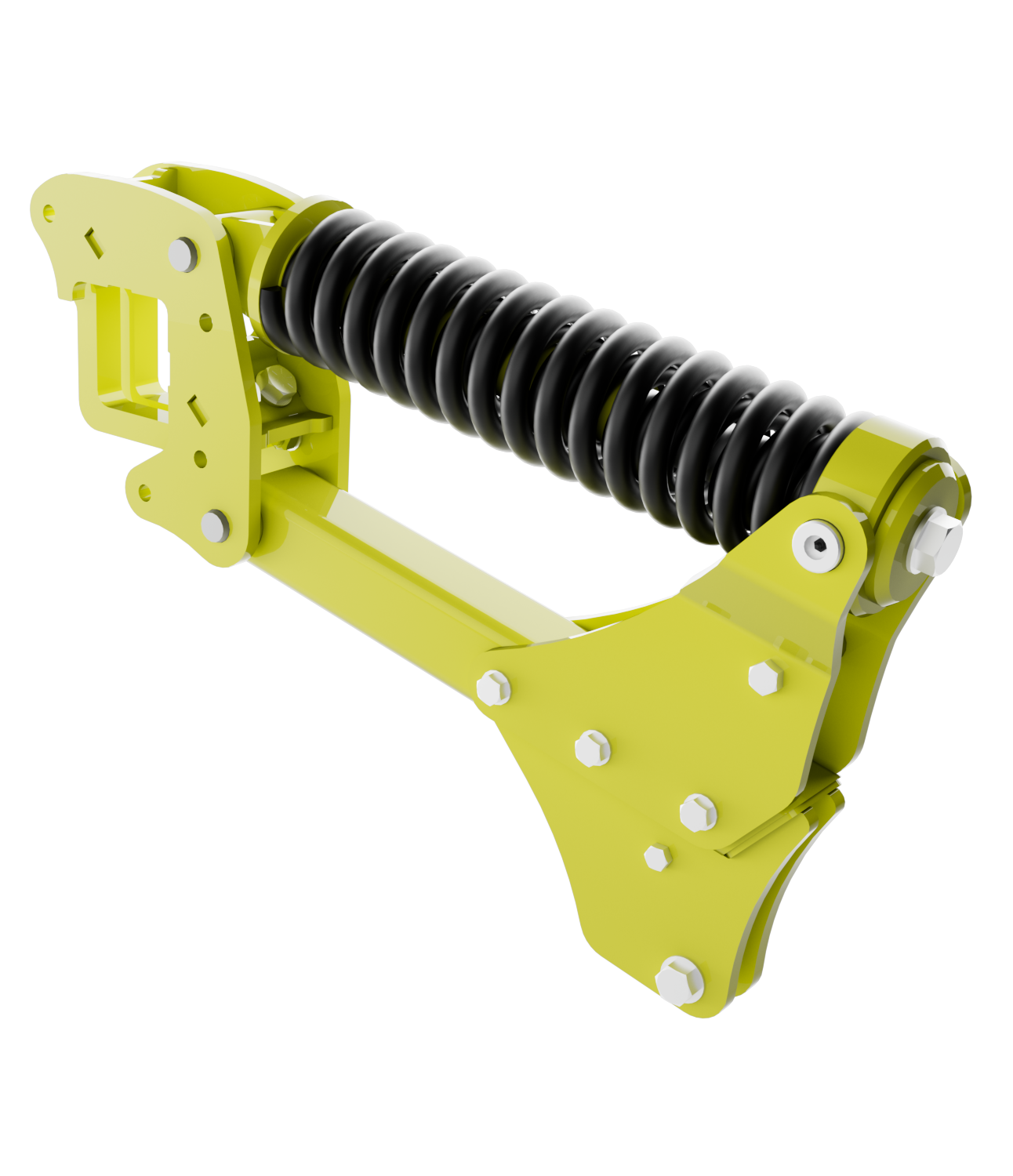

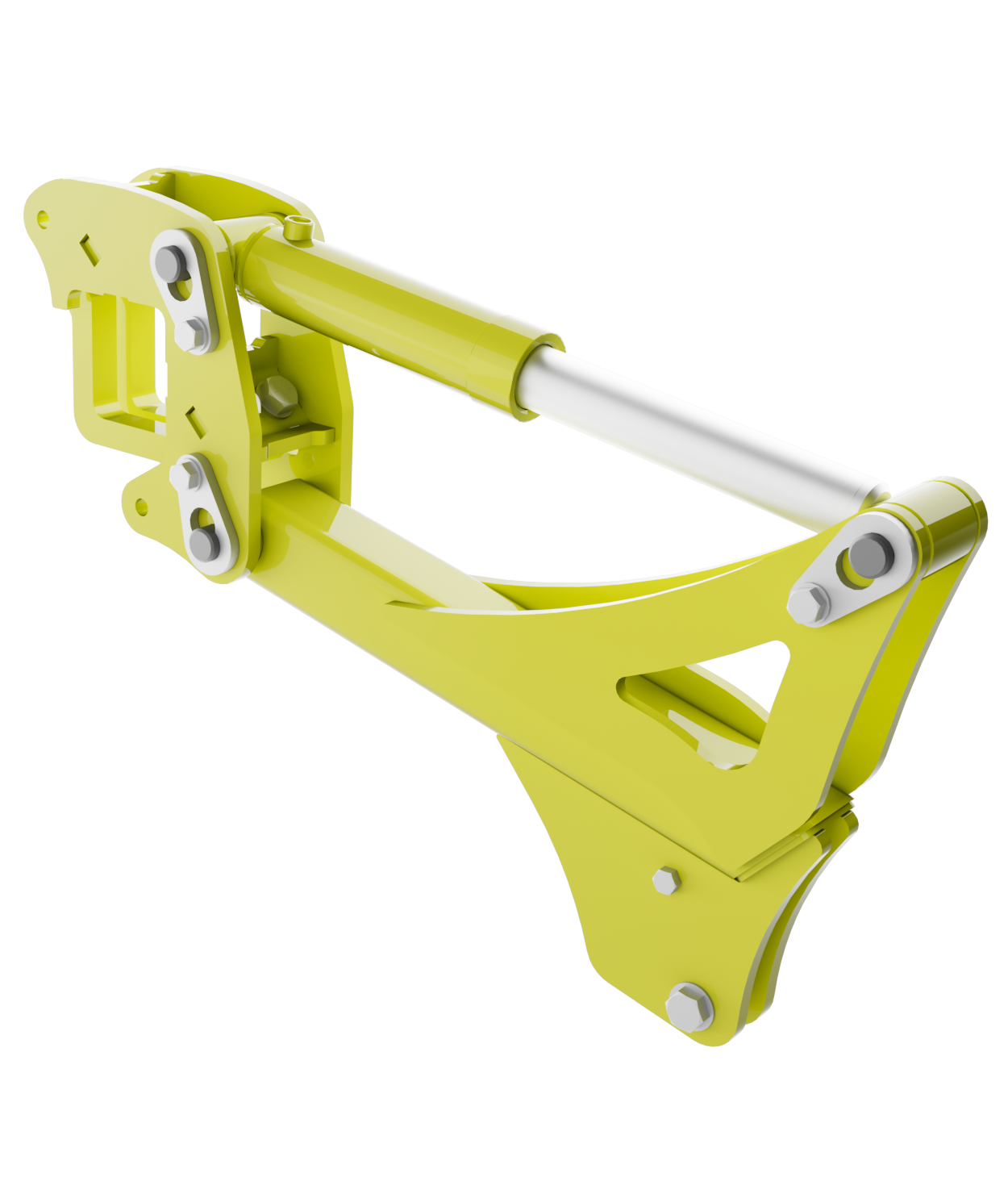

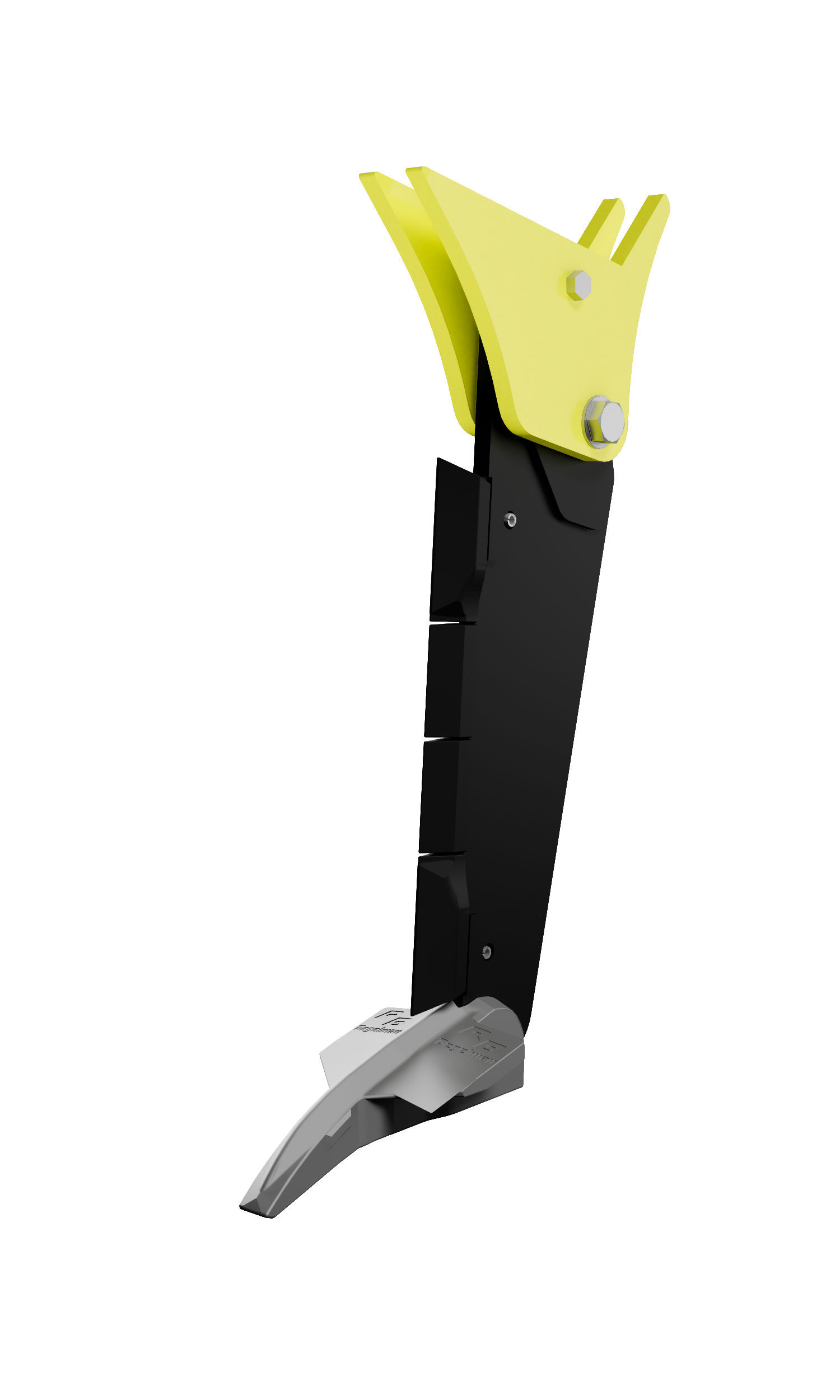

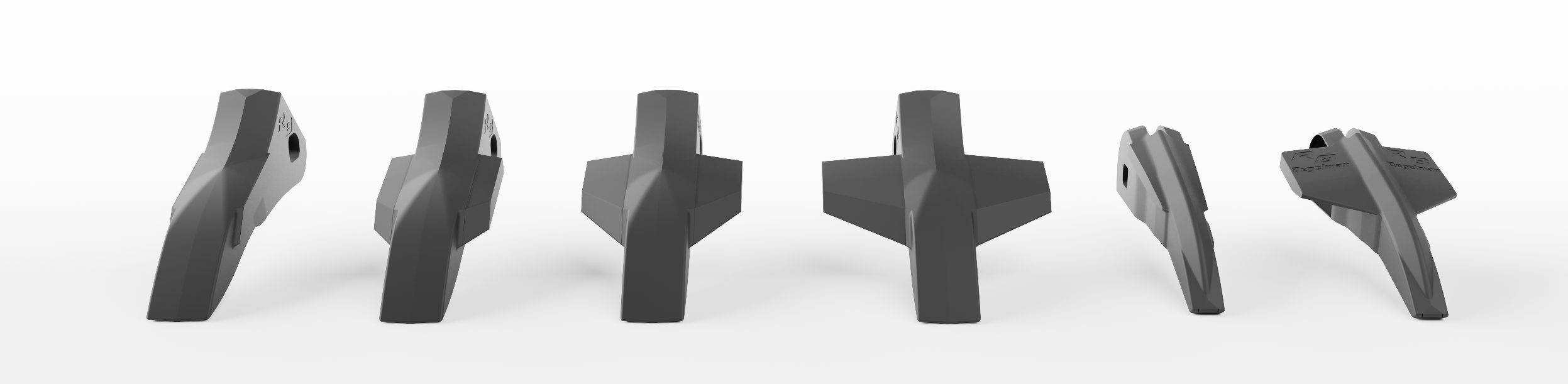

Introducing the all new HDSR line of Heavy Duty Staggered Rippers from Degelman. When your operation needs something more than conventional tillage, look no further. The HDSR offers aggressive, industry leading 24” maximum ripping depth. With the under frame clearance of 44”, there’s plenty of room for crop residue and rocks to pass through the machine. It also makes changing points easier and safer.

HDSR stands for exactly what it is- a Heavy Duty Staggered Ripper. Available in both a large wing machine and a mid-wing machine.

The large wing is compatible with 15 shanks on 20” spacing, or 11 shanks on 30” spacing. The mid-wing machine is compatible with 13 shanks on 20” spacing or 9 shanks on 30” spacing. Working sizes on these machines range from 22’ to 27’5".

Built and designed in a truly unique Degelman way, the HDSR Series of Staggered Rippers will be a game changer for your farming operation.