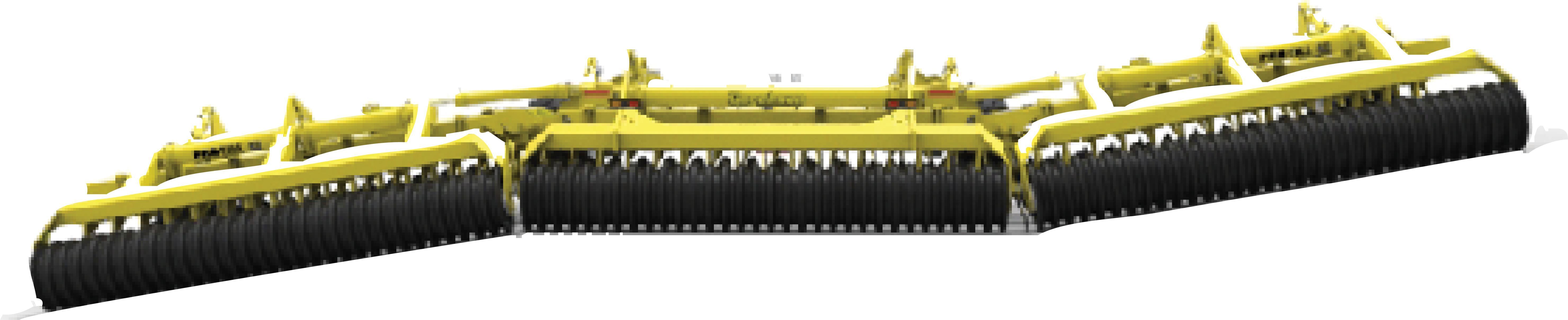

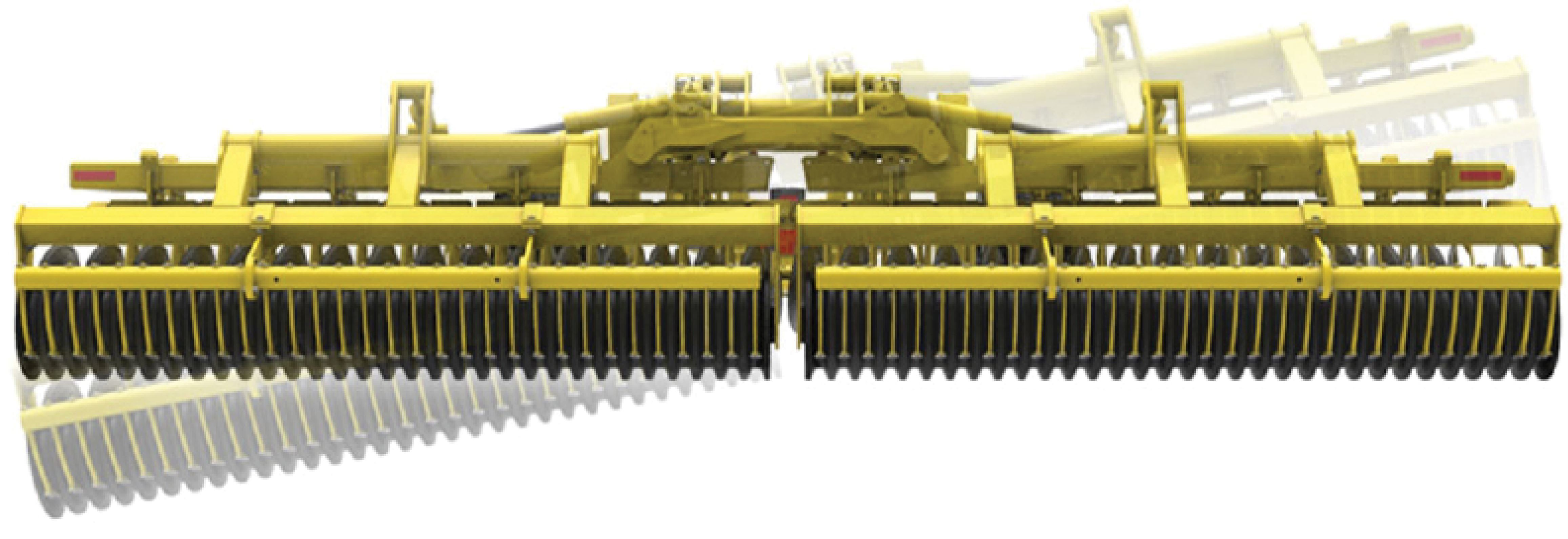

Whether you choose the all new exclusive LSTXE 600 or the LSTX 590 Otico roller, know that you are getting an excellent all-around packer with a unique corrugated ridge profile, which leaves a field finish designed to manage moisture and prevent soil erosion. Pro-Till’s furrow rollers outperform any typical cage roller, regardless of soil type or soil conditions. Proven effective in clay, sand, gumbo, and rocky soil, the furrow roller performs especially well in wet fields. Unlike a cage roller, the furrow roller is designed to shed soil to prevent plugging and reduce maintenance.

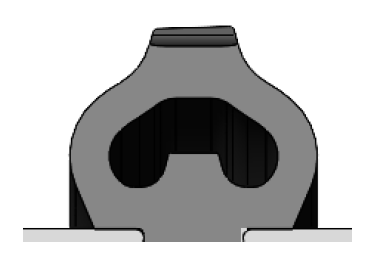

Semi-Pneumatic Technology

A special semi-pneumatic technology is integrated into the Pro-Till rollers making them work well in rocky soils and more resistant to wet conditions. Designed by OTICO of France, these exclusive rubber rollers are formulated from special rubber compounds. Uniquely molded over a high-strength steel core, they are also hollow, giving them the ability to flex each turn, partly absorb shock from stones and hard conditions, and also help shed mud with every revolution.