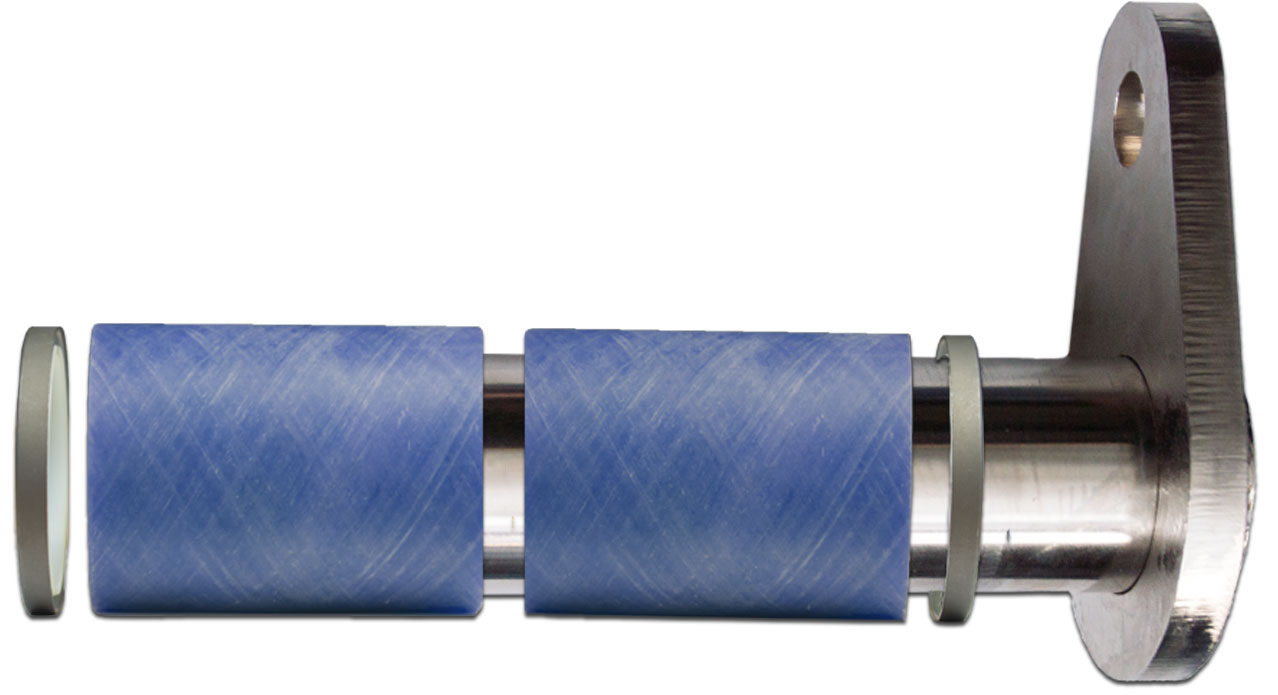

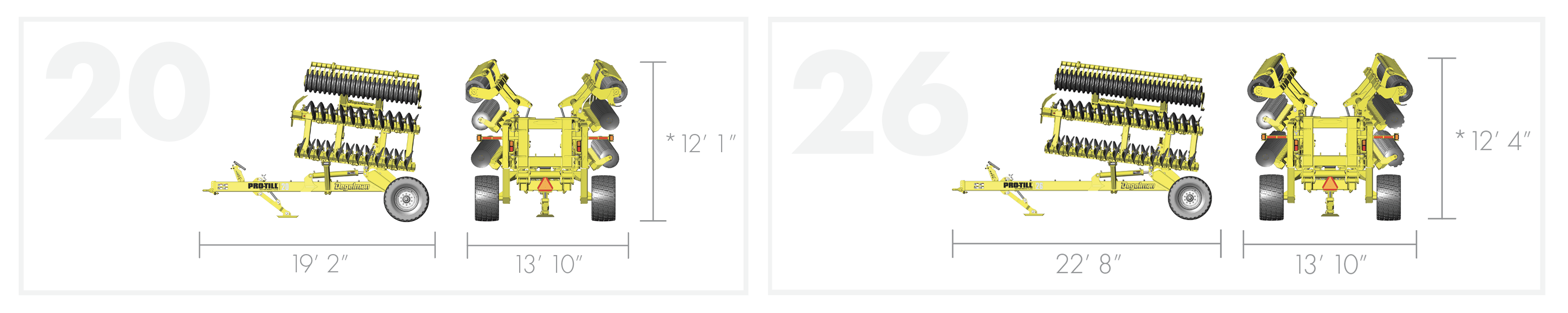

With the Pro-Till 20/26, Degelman Industries is able to offer the same high-speed, high-performance discs as our three-plex machines in a size that fits the 300 – 450 HP range, all without sacrificing our frame size, or the average weight per foot. In addition, we made the 20/26 Ft Pro-Till our first ever, completely greaseless, maintenance-free machine. It’s true “drop the pin and go” mentality.